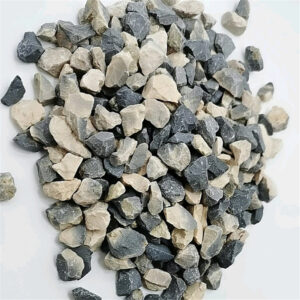

Calcined bauxite thermal stability, high mechanical strength and resistance to molten slags make Calcined Bauxite an ideal raw material in the production of shaped and unshaped refractories for the steel industry, foundries, glass and cement plants.

Item | KRB90 | KRB88 | KRB87 | KRB85 | KRB80 | RKB75 |

Al2O3(%) | 90.0min | 88.0min | 87.0min | 85.0min | 80.0min | 75min |

SiO2(%) | 3.5max | 5.5max | 7.0max | 8.0max | 10.0max | 16max |

Fe2O3(%) | 1.5max | 1.6max | 1.8max | 2.0max | 2.0max | 2.0max |

TiO2(%) | 3.8max | 4.0max | 4.0max | 4.0max | 4.0max | 4.0max |

CaO+MgO | 0.35max | 0.40max | 0.40max | 0.40max | 0.50max | 0.50max |

0.35max | 0.40max | 0.40max | 0.40max | 0.50max | 0.50 max | |

B.D(gm/cc) | 3.35min | 3.25min | 3.20min | 3.10min | 2.90min | 2.80 min |

Moisture | 0.3max | 0.3max | 0.3max | 0.3max | 0.5max | 0.5max |

1. Producing bauxite cement.

2. Abrasives.

3. Ceramics industry.

4. Chemistry industry for all kinds of aluminium compound.

5. Aluminium metallurgy.Â

6. Precision casting / Investment casting: bauxite grog fines can be made into mold for precision casting.

7.Refractory:Aluminium silicate refractory fiber, mixing magnesia and abuxite grog with binders to pour the molten steel ladle.

Â

Reviews

There are no reviews yet.